Multisorb FreshPax® Oxygen Absorber Packets. Spooled or Pre Cut Packet Sizes

Multisorb FreshPax® Oxygen Absorber Packets. Spooled or Pre Cut Packet Sizes

Low stock: 1 left

Couldn't load pickup availability

- International Delivery

- Bulk Buying Discounts

- Best-in-Class Products

FreshPax® from Multisorb are market leading, high performance oxygen absorbers for use with foodstuffs and other sensitive products vulnerable to degradation.

Available in a variety of packet sizes either pre-cut or spooled on a roll.

Multisorb FreshPax are a ‘best in class’ oxygen absorber packet designed to protect sensitive foodstuffs and other products in the supply chain.

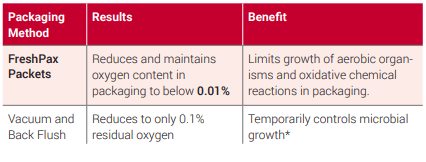

Multisorb FreshPax protect packaged foods against the usual harms including growth, mould, color change and the general spoilage that occurs when food loses it’s nutritive values and quality. FreshPax deoxidiser sachets irreversibly absorb oxygen from inside a sealed packaging environment to less than 0.01% and continue to maintain this.

Multisorb FreshPax both protect food and extend shelf life

The department of food science at Cornell University conducted a study that measured how effective FreshPax sachets were in extending the shelf lives of oxygen sensitive foods and other produce.

The study found even after simulating extreme testing conditions that when used in the likes of commercial bread and cheese, decreased mould spoilage was recorded as well as a considerable increase in shelf life.

It was also found in the study that the use of FreshPax packets can prevent the formation of n-hexanal and similar harmful compounds in high fat content foods that are prone to oxidative rancidity.

Advantages

- Shelf life extension.

- Minimal need for additional additives.

- Growth prevention against aerobic pathogens and organism that cause spoil.

- Absorbs oxygen from within the packaging as well as from that which may permeate the packaging as can sometimes be the case with vacuum packaging and gas flushing.

- Food grade moisture absorbing packets produced using food grade materials only.

Applications for FreshPax®

- Smoked, cured & processed meats.

- Pastries, bread & cakes.

- Nuts & crisps.

- Sweets and confectionary.

- Teas and coffees.

- Dried fruit and vegetables.

- Pre made meals.

- Vitamins and supplements including nutraceuticals.

- Asset preservation. Artwork, archive and artefact preservation.

- Herbs and spices.

Benefits of Multisorb FreshPax

- Counters the degradation that can be caused by oils and polyunsaturated fats.

- Excellent aroma preservation with teas and coffees retaining that fresh roasted flavour when packaged with FreshPax®.

- FreshPax oxygen absorbers for dehydrated food prevent oxidation of oleoresins in spices.

- Inhibits oxidation of vitamins A,C, & E.

- Inhibits mould growth in natural cheeses and other dairy products by fermentation.

- Can delay the onset of non-enzymatic fruit browning in fruits and some other vegetables.

- Counteracts condensation.

FreshPax® Oxygen Absorbers vs alternative solutions

Multisorb FreshPax packets can be incorporated into your current packaging methods, when vacuum packaging and gas flushing the inclusion of FreshPax® decrease the time it takes to deoxygenate the packaging enclosure. Gas flushing and vacuum sealing alone are limited in their efficacy because they only serve to dilute the oxygen which can mean defected products through early spoilage.

FreshPax oxygen absorbers work as a type of modified atmosphere packaging in that they reduce oxygen levels within the space, far below what could be achieved by vacuum sealing and gas flushing alone. When used together they form a complete solution.

Optimal use of FreshPax

Your chosen flexible packaging film will need to have an adequate barrier for oxygen permeability. A good starting point is to use a barrier foil with a sufficiently low moisture vapour transmission rate

- Packaging should be sufficiently heat sealed hermitically with a 3/8″ width heat sealer.

- Supply chain conditions, storage and distribution for the product packaging should be evaluated.

- Packaging design should allow for free and easy circulation of air where possible. This is preferred to a vacuum sealing approach which essentially compresses the packaging.

- Activity between food and water should be determined and monitored.

Available sizes

Pre-cut pieces

- VALSKUFRPX30C: FreshPax® 30 / 9000 pcs per case / 02-03117CG01.

- VALSKUFRPX50C: FreshPax® 50 / 7200 pcs per case / 02-03117CG02.

- VALSKUFRPX100C: FreshPax® 100 / 4000 pcs per case / 02-03117CG03.

- VALSKUFRPX30S: / FreshPax® 30 10K Spooled / 02-3115CG01.

Spooled on a reel

- VALSKUFRPX30S / FreshPax® 30 10K Spooled / 02-3115CG01.

- VALSKUFRPX50S / FreshPax® 50 8K Spooled / 02-3115CG02.

- VALSKUFRPX100S / FreshPax® 100 4.5K Spooled / 02-3115CG03.